Some people who use in vitro diagnostic reagents or instruments find that they either malfunction or think that they are not as advertised by the merchant. In various countries, the auditing of medical devices and reagents is very strict. So why do these failures occur?

Seamaty has compiled a few common questions about faults in in vitro diagnostic reagents and devices below.

The main reasons for problems with diagnostic reagents are as follows.

A. The place of use is home.

The products involved are human chorionic gonadotropin test strips, blood glucose test strips and ovulation prediction test strips. The main reasons for the incidents were the quality of the products themselves or improper handling by the users.

B. The place of use is medical institutions and others.

-

a) Quality: The product was originally defective products.

-

b) Transportation: The product was inverted, crushed or collided during transportation. Transportation does not meet the requirements of cold chain transportation, etc..

-

c) Storage: the temperature is too low (causing the product to freeze), moisture, etc.

-

d) Packaging, marking: reagents are missing, labels are incorrectly printed or posted backwards, barcode is wrong or abnormal, etc.

-

e) Supporting instruments: instruments are not matching. Product supporting instrument parts failure (including incomplete cleaning, sample needle contamination, etc.), instrument aging, etc.

-

f) improper operation: failure to properly conduct calibration procedures (including the use of non-matching calibrators, irregular use of calibrators, failure to calibrate after batch number replacement, failure to perform blank calibration, failure to calibrate after instrument overhaul, etc.), misuse, mixed batch use of reagents, improper sample handling operations or contamination, etc.

A. The place of use is home.

Most of the products involved are blood glucose meters. The main reasons for errors are patients' operation errors, poor quality of blood glucose instruments or measurement deviations.

B. The place of use is medical institutions and others.

-

a) Instrument quality problems, unstable performance.

-

b) Instrument internal, accessory/parts failure or damage: internal circuit damage, motherboard failure, etc., sample injection needle wear or plugged hole, aging connection tube, chip damage, etc.

-

c) Software problems (including virus in the computer).

-

d) Matching reagent problems: mismatch or matching reagent quality problems.

-

e) Improper operation of the instrument.

From the causes of adverse events, the main reasons for the problems of in vitro diagnostic reagents and equipment are transportation, storage, matching reagents and instruments, and the standardization of user operation.

If your medical equipment or reagents fail, you can try to investigate the causes from these aspects. Hope this helps you!

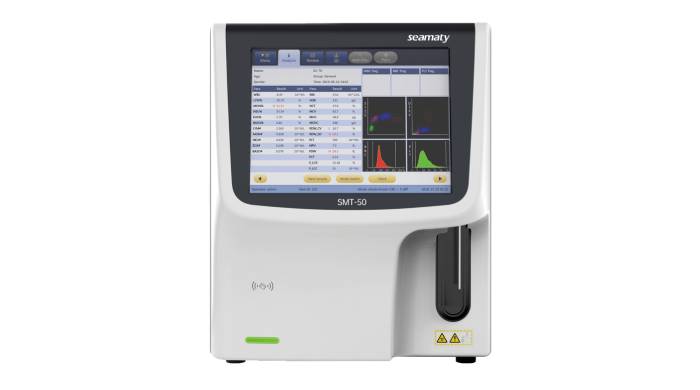

Seamaty portable (POCT) automatic biochemical analyzer is less maintenance. No liquid circuit, pump valve and other wearing parts inside the instrument. Single-participant reagent tray supporting the use of cleaning-free, maintenance-free.

In addition, the SMT-120 biochemistry analyzer requires no sample pre-treatment, no diluent addition, only 3-step operation (sample addition → sample release → result reading. Let the physician no longer worry about the complicated operation of the instrument.

Seamaty biochemistry analyzer is operated automatically throughout the whole process, with online fault diagnosis and network upgrade reminder function, helping you to grasp the operation of the instrument in real time.

Seamaty's biochemical reagent tray adopts micro-controlled flow design. The shelf life is up to 1 year.