release time:2023-06-12 14:32:01

Biochemical analyzers are crucial diagnostic instruments widely used in clinical laboratories. They provide essential information for physicians to assess patient health, monitor diseases, and create effective treatment plans. The accuracy of these analyzers directly impacts the reliability of test results. To ensure utmost precision, quality control tests must be conducted prior to using the instrument.

Biochemistry analyzers are indispensable medical devices found in hospitals, clinics, and laboratories. They analyze blood and other body fluids to measure various biochemical indicators, including liver and kidney function, myocardial diseases, blood lipids, sugars, specific proteins, and electrolytes. By combining these results with clinical symptoms, healthcare professionals can diagnose diseases and devise appropriate treatment strategies.

Biochemistry analyzers utilize advanced technology and algorithms to provide precise measurements of biomarkers. These instruments are designed to handle large volumes of samples efficiently, delivering accurate results in a timely manner. The ability to swiftly analyze a wide range of parameters makes biochemistry analyzers invaluable in modern healthcare settings.

Quality control in biochemistry analyzers is known as Internal Quality Control (IQC). It involves using control materials and clinical samples during analysis to observe analytical errors. This process helps establish precise and sensitive control procedures, enabling prompt detection of errors caused by technical operations, reagents, or instrument performance changes. By controlling analytical errors within acceptable limits, IQC ensures reliable and accurate test results.

IQC consists of several components, including control materials, calibration, and regular monitoring. Control materials, also known as quality control samples, contain known concentrations of specific analytes. These materials are analyzed alongside patient samples to validate the accuracy and reliability of the biochemistry analyzer.

Calibration is another crucial aspect of IQC. It involves adjusting the instrument to ensure it provides accurate measurements. Regular monitoring is essential to assess the long-term performance and stability of the biochemistry analyzer. By regularly monitoring control results and comparing them against predefined acceptable ranges, laboratories can identify any deviations and take appropriate corrective actions.

The reliability of test results from biochemistry analyzers relies on the continuous monitoring of control materials. This approach guarantees the accuracy of reported results and allows for comparison of test outcomes across different laboratories. Accurate and reliable test results are crucial for clinicians, as they form the basis for effective patient treatment and impact the assessment of patients' conditions. Thus, quality control testing is an essential step that cannot be overlooked.

Accurate diagnosis is the cornerstone of effective healthcare. Biochemistry analyzers play a pivotal role in supporting clinicians in diagnosing diseases and developing appropriate treatment plans. By ensuring the accuracy and reliability of test results, quality control in biochemistry analyzers minimizes the risk of misdiagnosis and ensures that patients receive the most appropriate care.

Moreover, quality control testing enhances the comparability of test results across different laboratories. This comparability is vital in collaborative research, clinical trials, and disease surveillance programs. Consistent and reliable test results obtained through rigorous quality control measures enable healthcare professionals to make informed decisions based on standardized data.

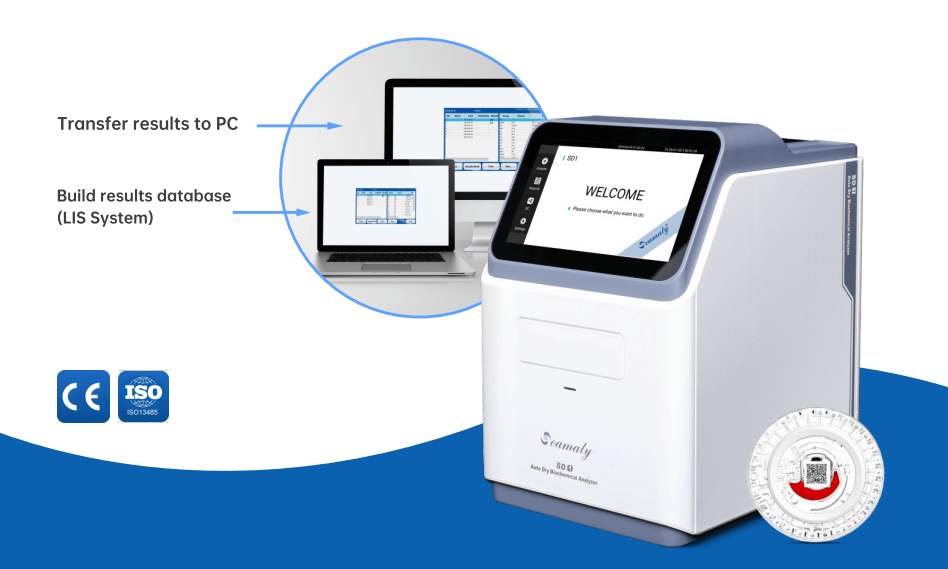

Seamaty, a leading manufacturer in the industry, has achieved ISO 13485:2016 international quality management system certification from TUV Rheinland. Additionally, they have obtained national intellectual property management system certification. With a state-of-the-art factory equipped with GMP level cleanrooms and cutting-edge laboratories, Seamaty ensures top-notch product testing and production. Their commitment to quality is evident through the utilization of advanced automated production lines, a skilled workforce, and a dedicated quality control team. The company's first-class laboratories, including GMP 10,000 level, guarantee rigorous testing of their products for vibration, power surges, shock, and other crucial aspects. Rest assured, Seamaty prioritizes the reliability and safety of their products for clinical use in diverse environments.

Quality control plays a vital role in confirming that biochemistry analyzers operate within intended performance parameters. It serves as a fundamental basis for obtaining reliable test results, which are crucial for clinicians in developing treatment plans, assessing patient health, and monitoring disease prevention. Consequently, the implementation of quality control in biochemical analyzers is an indispensable testing step that ensures accuracy and instills confidence in the results obtained. By adhering to stringent quality control practices, healthcare professionals can deliver optimal patient care and advance medical knowledge through accurate and reliable diagnostic testing.

2023-05-30

Discover what is dry chemistry analyzer and its advantages. And how the Seamaty SD1 dry chemistry analyzer revolutionizes point-of-care testing. Enhance workflow efficiency, improve patient care, and achieve cost-effectiveness in medical diagnostics.

2022-03-04

This article introduces the latest advanced technology and the performance advantages of each major component parameter of the current fully automatic biochemistry analyzer.

2021-09-26

A hematocrit analyzer is a device used to perform a complete blood count (CBC) or hemogram. It allows quantitative and qualitative analysis of the elements formed in the blood. Examples include red blood cells, white blood cells and platelets. Blood cell analyzers are mainly used in medical analysis laboratories or hospitals with hematology departments.